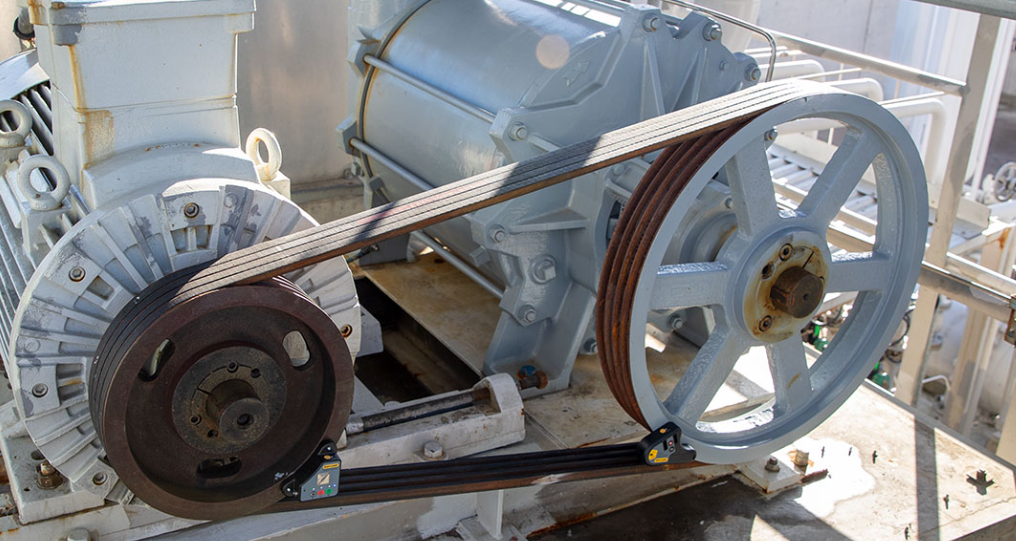

For various machine units belt alignment is the most important part to maintain their efficient performance. It ensures that all of your equipment is operating at maximum efficiency and effectiveness.

When you’re making sure that your equipment is aligned correctly, you want to make sure that you’re using the right tools for the job. There are many different types of alignment tools available, but some are better than others.

Recommendations for the best belt alignments for machine units:

For conveyors that need to carry heavy loads, we recommend a four-way stretch wrap set-up with an offset centerline. This will allow your conveyor to handle more weight while reducing tension on the belts and minimising noise.

For machines that are used in high-moisture environments (such as food processing plants), we recommend a two-way stretch wrap with an offset centerline. This will help keep water from coming into contact with the rubber and causing premature wear.

If you plan on using your machine unit in areas where it will be exposed to extreme heat or cold, it is recommended using one of our protective products like our Thermoplastic Protector or Weatherproof Protector. This will help preserve the rubber while also protecting it from UV damage.

How to check belt alignment?

First, make sure that you have a good understanding of how cardan shaft alignment works on your particular machine unit. If you don’t know what you’re doing, don’t try to do it yourself! Call in a professional who knows how to align belts properly for optimal performance.

Second, keep an eye out for signs of wear and tear on your machine units’ belts. If you notice any cracks or fraying, get them replaced immediately; this will help prevent accidents before they happen!

Third, be sure that all bolts are tightened down properly before operating your machinery again after maintenance or repairs have been performed on them.

Why are Machine Units a critical part of any manufacturing or industrial process?

They drive the work, and they need to be in peak condition at all times. That’s why it’s so important to keep your belt alignment in optimal shape—without it, your machine unit will perform poorly and run the risk of failure.

When you’re looking to optimise your machine unit, there are a few factors to take into consideration. You want to make sure that the belt alignment is correct. A poorly aligned belt can lead to reduced productivity and increased maintenance costs. For more information visit our Website